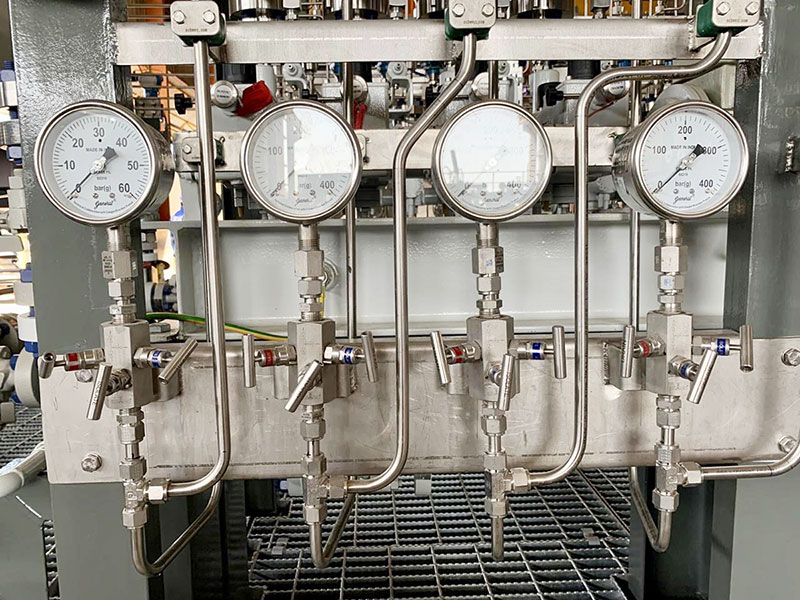

Hydraulic & Instrumentation Tubes are essential components in hydraulic and instrumentation systems and they are used to protect and partner with other components devices or instruments to secure the safe and trouble-free operations of oil and gas plants, petrochemical processing, power generation and other critical industrial applications.

Hydraulic tubes and instrumentation tubes in a comprehensive range of corrosion-resistant stainless steels and nickel alloys in small diameter from 1/8" to 2" OD. All sizes are supplied with smooth surfaces and tight dimensional tolerances reducing the risk of leakages when connecting tubes with couplings.

Main Standard and Grades for Hydraulic and Instrumentation Application:

Standard:

ASTM: A213, A269, B163, B167, B668, A632, A789, B444

ASME: SA213, SB163, SB167, SB 668, SA789, SB444

EN 10216-5

Main Grades in ASTM Type:

TP304/TP304L, TP316/TP316L, TP316Ti, TP321/TP321H

UNS S31803, S32205, S32750, S32760, S31254

UNS N08800, N08825, N08904, N06625, N04400

and other grades with modified chemical composition as per specifications.

For hydraulic tubes and instrumentation tubes special application, we use special production and packing process to make sure all the tubes are in the super clean conditions when delivery to our clients:

1. Strong degreasing

All the tubes are degreasing in a specially made alkaline bath to clean and passivate it.

2. Thorough cleaning

After degreasing, every tubes will be cleaned by pure water with ultrasonic cleaning technology. When necessary, we will use the sponge and high-pressure air to blown through the interior to clean out any impurities of each tube.

3. Bright annealing

All sizes of the tubes are supplied bright annealed condition with 100% hydrogen gas protection.

4. Polishing(MP or EP)

When client need, we can arrange mechanical polishing or electrolytic polishing to provide a super bright and smooth finish conditions to meet client’s application.

5. Excellent Packaging

All tubes with outer diameters larger than 6 mm are supplied with plugged ends. Every tube put into a separate plastic bags to avoid scratch and packed into strong wooden case for shipment.

In Hydraulic and Instrumentation applications, the pipes and tubes are divided into five sub-segments based on application and specific requirements:

1. Safety Systems

2. Hydraulic Systems

3. Process Impulse Lines

4. Subsea Equipment

5. Compressors

Typical products:

Instrumentation & Control Lines

Pneumatic Lines

Signal Transmission Lines

Downhole, hydraulic and chemical injection control lines

Control lines in subsea umbilicals

Flowline control line tubing for pipe-in-pipe bundles

Hydraulic tubing for control measuring devices and pumps

Control and injection line tubing for subsea equipment

Topside instrumentation and impulse lines

Well chemical injection units

Autoclave and high pressure applications

Previous Power Generation

Next Chemical Industry

Navigation

Tel.: +86 512 6586 3562

Phone: +86 152 5043 1153

Fax: +86 512 6586 3052

E-mail: sales@sincoometal.com

Address: Room 508, Building 23, Times Square, Suzhou Industrial Park, (Jiangsu) Pilot Free Trade Zone, China 215000